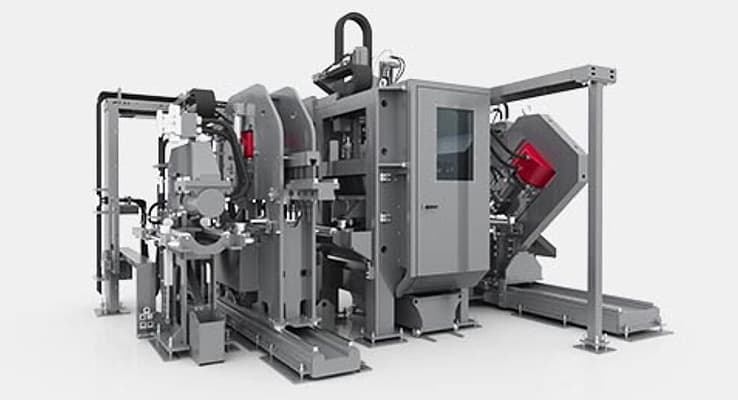

Beam Layout Welding Copper

There are many differences between beam layout welding, H beams, and when it comes down to the application. It can be used for many purposes. These are just two of the many things that will help you identify an H beam from one.